- 66

- 13 181 864

Dr. D-Flo

Приєднався 7 лис 2016

My name is David Florian, and I go by the moniker Dr. D-Flo in the online world. My content focuses on digital fabrication techniques, which are any workflows that rely on a computer to control the manufacturing process. This includes both additive (e.g., 3D printers) and subtractive (e.g., CNC mills) machines. In the past, these devices were large, complex, and only found in industrial warehouses. But today, for a couple hundred dollars anyone can purchase a 3D printer, CNC router, or laser cutter.

This channel focuses on not only how to program and use these instruments but also how to build them. My video guides cover a spectrum of information for both the beginner and the seasoned DIYer. I error on the side of providing too much information because it can be frustrating to watch a video and leave with more questions than answers.

I am always looking for project collaborators and industrial partners, so feel free to reach out to me through the email below or on my forum.

This channel focuses on not only how to program and use these instruments but also how to build them. My video guides cover a spectrum of information for both the beginner and the seasoned DIYer. I error on the side of providing too much information because it can be frustrating to watch a video and leave with more questions than answers.

I am always looking for project collaborators and industrial partners, so feel free to reach out to me through the email below or on my forum.

SCREWing Around with a $20K Pellet Extruder - Large Format 3D Printer (Part 7)

This behemoth boasts a flow rate of over 5 kg/hr., chewing through and spitting out material faster than any desktop 3D printer.

Large Format 3D Printer Build Series: ua-cam.com/play/PLZ9ac-f1U5V-FCBdhjv56bcvn9yc6JSfY.html

Screw Extrusion Guide: www.drdflo.com/Extrusion.html

Electrical Cabinet Building: drdflo.com/Electrical-Cabinet.html

Basics of Screw Extrusion Video: ua-cam.com/video/cIh0n2zOCfM/v-deo.html

Featured Products:

MDPE10 Screw Extruder: massivedimension.com/products/mdpe10-massive-dimension-direct-print-particle-extruder

IC3D's Recycled PETG: www.ic3dprinters.com/shop/recycled-petg/

Brady 210 Labeler: amzn.to/45sHjeK

LED Sheets: amzn.to/4b3HPAY

Table of Contents:

00:00 - Introduction

00:46 - Filament vs. Pellet Extruder

02:23 - MDPE10

03:39 - Screw

05:35 - Heating Zones

06:29 - Pellet Feeding

07:30 - Motor

08:23- Cost

09:01 - New Electrical Cabinet

20:10 - Temperature Probes

24:15 - “Tap” Probing

24:56 - Lattice Sleeve

26:43 - LEDS

28:36 - Umbilical Cable Management

29:10 - Testing Max Extrusion

31:18 - Benchy

35:19 - Corner Flower Planter

In this video, we'll explore how this extruder achieves such a massive throughput, including a detailed look at its features and a custom-built electrical cabinet to power its hefty needs. I'll walk you through the setup, wiring, and some incredible test prints that push my large format 3D printer to its limits. Plus, we'll compare it to the smaller MDPH2 and discuss the unique benefits of a larger screw extruder. Don't miss out on seeing this powerhouse in action!

Large Format 3D Printer Build Series: ua-cam.com/play/PLZ9ac-f1U5V-FCBdhjv56bcvn9yc6JSfY.html

Screw Extrusion Guide: www.drdflo.com/Extrusion.html

Electrical Cabinet Building: drdflo.com/Electrical-Cabinet.html

Basics of Screw Extrusion Video: ua-cam.com/video/cIh0n2zOCfM/v-deo.html

Featured Products:

MDPE10 Screw Extruder: massivedimension.com/products/mdpe10-massive-dimension-direct-print-particle-extruder

IC3D's Recycled PETG: www.ic3dprinters.com/shop/recycled-petg/

Brady 210 Labeler: amzn.to/45sHjeK

LED Sheets: amzn.to/4b3HPAY

Table of Contents:

00:00 - Introduction

00:46 - Filament vs. Pellet Extruder

02:23 - MDPE10

03:39 - Screw

05:35 - Heating Zones

06:29 - Pellet Feeding

07:30 - Motor

08:23- Cost

09:01 - New Electrical Cabinet

20:10 - Temperature Probes

24:15 - “Tap” Probing

24:56 - Lattice Sleeve

26:43 - LEDS

28:36 - Umbilical Cable Management

29:10 - Testing Max Extrusion

31:18 - Benchy

35:19 - Corner Flower Planter

In this video, we'll explore how this extruder achieves such a massive throughput, including a detailed look at its features and a custom-built electrical cabinet to power its hefty needs. I'll walk you through the setup, wiring, and some incredible test prints that push my large format 3D printer to its limits. Plus, we'll compare it to the smaller MDPH2 and discuss the unique benefits of a larger screw extruder. Don't miss out on seeing this powerhouse in action!

Переглядів: 35 498

Відео

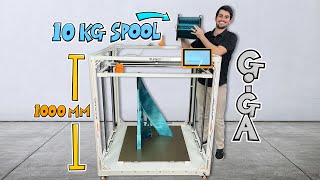

Affordable Large Format 3D Printer! (Elegoo OrangeStorm Giga Review)

Переглядів 113 тис.2 місяці тому

Can a large format 3D printer be both affordable and reliable? Watch to find out! OrangeStorm Giga: www.elegoo.com/pages/elegoo-orangestorm-giga IC3D's 10 kg PETG: www.ic3dprinters.com/shop/recycled-petg/ 📷 Follow Dr. D-Flo on the Gram: dr.dflo 🛒 D-Flo's Amazon Store: www.amazon.com/shop/dr.d-flo Dive into Dr. D-Flo’s review of the Elegoo OrangeStorm Giga, which is not just anothe...

Rack and Pinion Upgrade: Key to Faster Large Format 3D Printing (Part 6)

Переглядів 80 тис.4 місяці тому

3X Speed and reliability with custom rack and pinion linear actuators for my large format 3D printer. Files, Parts, and Info: www.drdflo.com/LF3DP.html Large Format Printer Playlist: ua-cam.com/play/PLZ9ac-f1U5V-FCBdhjv56bcvn9yc6JSfY.html D-Flo's Amazon Store: www.amazon.com/shop/dr.d-flo New MDPE10 Extruder: massivedimension.com/products/mdpe10-massive-dimension-direct-print-particle-extruder ...

Recycling 3D Prints and Waste Plastic into Filament (PET & PLA)

Переглядів 217 тис.8 місяців тому

Transform your unwanted 3D prints and household plastics into eco-friendly 3D printer filament! 🌱 More Extrusion Info: www.DrDFlo.com/Extrusion.html Filabot Recycling Lineup: www.filabot.com/products/recycling-setup-filabot-reclaimer-and-filabot-pelletizer Shredii: actionbox.ca/products/shredii-5 D-Flo's Amazon Store: www.amazon.com/shop/dr.d-flo 📷 Follow Dr. D-Flo on the Gram: dr...

Mastering CNC Plasma Cutting: Technology, Operation, and CAM

Переглядів 119 тис.8 місяців тому

How to setup, program, and operate a CNC plasma table 🔥 More Plasma Info: www.drdflo.com/Plasma.html DIY Vacuum Lifter Plans: drdflo.com/Vacuum-Lifter.html D-Flo's Amazon Store: www.amazon.com/shop/dr.d-flo 📷 Follow Dr. D-Flo on the Gram: dr.dflo Video Description: Welcome to Dr. D-Flo’s mega guide on how to setup, operate, and perfect cuts on a CNC plasma cutter. This video cover...

How to Extrude 3D Printer Filament (Basics of Screw Extrusion)

Переглядів 70 тис.Рік тому

Making 3D printer filament from cheap pellets 🧵 More info: www.DrDFlo.com/Extrusion.html D-Flo’s Amazon Store: www.amazon.com/shop/dr.d-flo 📷 Follow Dr. D-Flo on the Gram: dr.dflo Equipment: EX6 Extruder: www.filabot.com/products/filabot-ex6-filament-extruder Spooler: www.filabot.com/products/filabot-spooler Airpath: www.filabot.com/products/filabot-airpath Filameasure: www.filabo...

Fabricating a Mill Enclosure for Flood Coolant

Переглядів 69 тис.Рік тому

Contain the metal chips and coolant 💦 with a custom enclosure BOM and Info: drdflo.com/CNC-Mill.html D-Flo’s Amazon Store: www.amazon.com/shop/dr.d-flo 📷 Follow Dr. D-Flo on the Gram: dr.dflo This project started with a relatively simple goal: enclose my DIY CNC mill to prevent metal shavings from flying all over my garage. However, I decided that if I was going to build an enclos...

Building a Large Format 3D Printer - Part 5: Upgrades!

Переглядів 279 тис.Рік тому

Part 5 of this massive printer build includes an enclosure, closed-loop motors, and electronics upgrades! Files, Parts, and Info: www.drdflo.com/LF3DP.html Large Format Printer Playlist: ua-cam.com/play/PLZ9ac-f1U5V-FCBdhjv56bcvn9yc6JSfY.html D-Flo's Amazon Store: www.amazon.com/shop/dr.d-flo 📷 Follow Dr. D-Flo on the Gram: dr.dflo Part 5 is packed with serious upgrades and creati...

Building a Large Format 3D Printer - Part 4: Printing

Переглядів 792 тис.2 роки тому

Building a Large Format 3D Printer - Part 4: Printing

Building a Large Format 3D Printer - Part 3: Electrical

Переглядів 142 тис.2 роки тому

Building a Large Format 3D Printer - Part 3: Electrical

Building a Large Format 3D Printer - Part 2: Motion

Переглядів 190 тис.2 роки тому

Building a Large Format 3D Printer - Part 2: Motion

Building a Large Format 3D Printer - Part 1: Pellet Extruder

Переглядів 345 тис.2 роки тому

Building a Large Format 3D Printer - Part 1: Pellet Extruder

5 Useful 3D Prints! (Original Models)

Переглядів 178 тис.2 роки тому

5 Useful 3D Prints! (Original Models)

My First Industrial CNC Plasma Table: ShopSabre SideKick 8 (Features, Specs, and Cutting)

Переглядів 32 тис.2 роки тому

My First Industrial CNC Plasma Table: ShopSabre SideKick 8 (Features, Specs, and Cutting)

Machining Groomsmen Gifts for My Wedding (w/ 3D Toolpaths and Soft Jaws)

Переглядів 9 тис.2 роки тому

Machining Groomsmen Gifts for My Wedding (w/ 3D Toolpaths and Soft Jaws)

Building an Epic DIY 3D Printer: Voron 2.4 with Mods!

Переглядів 685 тис.2 роки тому

Building an Epic DIY 3D Printer: Voron 2.4 with Mods!

Industrial 3D Scanning and Printing with 3DChimera (FFF & SLS)

Переглядів 44 тис.2 роки тому

Industrial 3D Scanning and Printing with 3DChimera (FFF & SLS)

5 Awesome Projects/Gifts for your CNC Router and How to Make Them

Переглядів 391 тис.3 роки тому

5 Awesome Projects/Gifts for your CNC Router and How to Make Them

Rigid Tapping with New Motor and VFD (DIY CNC Mill Upgrades 3)

Переглядів 128 тис.3 роки тому

Rigid Tapping with New Motor and VFD (DIY CNC Mill Upgrades 3)

Building a Selective Laser Sintering (SLS) 3D Printer!

Переглядів 477 тис.3 роки тому

Building a Selective Laser Sintering (SLS) 3D Printer!

What is Selective Laser Sintering (SLS) 3D Printing?

Переглядів 97 тис.3 роки тому

What is Selective Laser Sintering (SLS) 3D Printing?

Power Drawbar and Tool Offsets (DIY CNC Mill Upgrades 2)

Переглядів 56 тис.3 роки тому

Power Drawbar and Tool Offsets (DIY CNC Mill Upgrades 2)

AC Servo Motors and FogBuster Mist Coolant (DIY CNC Mill Upgrades 1)

Переглядів 106 тис.3 роки тому

AC Servo Motors and FogBuster Mist Coolant (DIY CNC Mill Upgrades 1)

Building a Plasma Table for Fasterproms

Переглядів 13 тис.3 роки тому

Building a Plasma Table for Fasterproms

Building the Electric CYBER Scooter

Переглядів 129 тис.3 роки тому

Building the Electric CYBER Scooter

The Electric Cyber Scooter (Preview)

Переглядів 4,7 тис.3 роки тому

The Electric Cyber Scooter (Preview)

Affordable Plasma Cutter for CNC (Cut50L)

Переглядів 61 тис.3 роки тому

Affordable Plasma Cutter for CNC (Cut50L)

How to Convert a Manual Mill to CNC

Переглядів 338 тис.4 роки тому

How to Convert a Manual Mill to CNC

How to Build a 3D Printer (The Ultimate Guide)

Переглядів 3,2 млн4 роки тому

How to Build a 3D Printer (The Ultimate Guide)

Nice

Love smart happy people. 🦾🤙

Bruh 18,5k

do these actually work now? I have seen a lot of really bad reviews for this.

what a video. Thank you!

This is quality content and well presented too. Regarding the set of machines, I am somewhat surprised that those are, well, "under engineered". For 17k I expect more sensors and actuators. Adjusting rates by hand is a thing of the past.

Now that you've got this thing printing, do you find yourself thinking of ways to use it often? I'm curious when it makes more sense to run a giant print versus manufacturing something using alternate methods. Really cool built regardless!

UA-cam suggestions for sure. He should make a sailboat and see how well it can actually sail

We produce shredder machine.we are a factory from China

Name and price of this printer?

It’s a DIY printer: ua-cam.com/play/PLZ9ac-f1U5V-FCBdhjv56bcvn9yc6JSfY.html&si=mfHRCUodBZe6KCrj

@@DrDFlo dang, a print volume that massive would be great, but I can't build anything like that myself, let alone code it

Too expensive and too hard to build🥲😁🤣

@@antonsemenyura5337 Oh it's quick build... only took me 2 years 😂

Hey big fan ive been following you since quite a while. I just wanna know how long does it take to print large scale items like tables,chairs(like in your videos).And what abput 3d printed homes. Ive been seeing a lot of those articles. How libg would it take for their huge printer to print a house ?@@DrDFlo

I would like to know the price of this machine.

Duet has a daughterboard for thermocouples why did you not use that?

Too much noise couldn’t get a consistent reading

The print qauilty is terrible.

Exquisite

very good.nice guy. i maked CNC machine in Japan.

She finally did something good 🤣

Awesome video! Everything I wanted to know and a whole bunch more that I was happy to learn!

I worked in the plastics industry when I was younger. I worked on Extruders, Injection moulders, Massive or rather Gigantic Vacuum formers, Conduit pipe bending and collar forming in baths of Hot Glycerin. As well as Custom made anything made out of plastics. Oh yes, we did Signs as well and had an in-house electrician to sign off on everything. Cool job. So, if 30 years ago you told me about 3D Printers and how everyone would have one in their home, I might just have believed you. But if you told me that a few years later again many of those people would have their own plastic extruders in their homes and some people even making their own little injection moulders well, i would never ever have believed you. The prices of industrial injection moulders and extruders were prohibitively expensive back then. The injection moulding machine its self was around $1M (Australian) and I was told the Moulds were around $500k per set in total. The mould in particular was for making McDonald's Tea Spoons. I can not wait to have my very own extruder for making 3D Printing Filament.

Hello dear sir built a frame for it 😊😅

Hello dear you could take off the axel screw up the handle and then see what you could do after that 😊😅

which engines are used along the axes? There is nothing about it in the BOM....

Very Nice Job ! This size printer really shows up the errors with the size of the extrude being 5mm. ( Helps me realize the errors in my smaller printer) Loved the Planter setup .Very ingenious !

0:48....vulcano cht nozzle = 70mm3s: super vulcano with dual vulcano cht inside (one "nozzle" without the tip act like a spacer) And you have almost 200mm3s (but try to keep it hot...in reality more like 150mm3+) It is possible to use multiple spools at once (few extruders , few heating zones , single nozzle...like in old multi colour nozzles ) to go over 500mm3s easly for pretty cheap , but it will be behemoth of a hotend (dont ask me how i know that , lets just say my smallest oldest (10y+) printer have 500mm+/- xyz and printed molds for composites)

Hey Dr. D-Flo, I'm back with another question, have you seen the Greenboy3D work on a diy pellet extruder? Could I have your thoughts on it? Thanks again!

I would have to get my hands on it, but as mentioned in this video the longer/larger the screw the better the performance (not just increased output but also less affected by irregular feeding of pellets)

@@DrDFlo thanks for your reply and input, can’t wait to see more from you!

26:31 the inductive sensor flag should go beside the sensor not in collision to it.. nice job👍🍺

An idea, on long runs you could add nutless supports that are pulled out from the bearing end when the head is close to the drive end. And they could act as a cable guide from the side

Awesome - very clear and nice video - everything in 1.5 hours that you must know abbout cnc plasm Where can i order the fluid for the watertable

Awesome video, kept me very much hooked the whole way through. Can't wait to see more upgrades. Just plain incredible work and thoroughly impressive just how many specialties you've needed to master to be able to do a project like this.

$15k and an headache 😂

A little tip on soldering those cup terminals: The easiest way to get a perfect joint every time is to tin the wire, then heat the cup from the side, melt it full of solder, stick the pre-tinned wire in and let it cool. If you want a visual guide, I believe the PACE soldering tutorial showcases this method.

The obvious question... "But why?"

You should check out the V-Spooler Easy Motor Drive. It uses a nema 17 stepper motor to drive the Spooler instead of a drill. I also recommend the Quiet Roller mod.

Why not just to to put big pellet extruder before printer and make filament, wind that to some buffer roll and after, just wire that freshly made filament to normal light-weight extruder of the printer? Cheaper and also no issues with retract

20k for that ???? I work 10 years in the plastics industry and that thing is a damn scam. Almost everything from 3D printing is actually extremely overpriced or actually a scam

You are still killing it. I love your content.

Those layer lines are breaking my 💜.

Song at 28:08 ?

As amazing as this thing is, it really upsets me how expensive this is at over $22,000, even if it's geared for "industrial use." It's not just "Massive Dimension" pellet extruders that cost so much. It seems to be industry-wide with some costing nearly $100,000. Maybe it's a bad comparison, but at this price, I could get a brand new car like you suggested. A car has significantly more technology, more parts, engineering, raw materials, and overhead that went into manufacturing them. Can someone explain the cost breakdown for these things?

Usually, it's an economy of scale problem. Let's say you're an extruder manufacturer, and it costs $5,000 for you to buy all the off-the-shelf and custom components plus labor for assembly. At $5,000, you are already priced out of the hobbyist market, and that doesn't even include the normal overhead to run a business (warehouse space, customer support, marketing, and salaries). Further, the extruder you're manufacturing is heavy, so an industrial motion platform is needed to move the extruder (robotic arm, bridge-style gantry system, etc.). So even if you could sell your extruder for $5,000 or let's say you sell it at a loss for $2,000 and plan to make money by selling plastic pellets (which is hard to do because pellets are everywhere and not locked down like say printer ink), there are very few people who have the means to afford this setup. So if I were doing the market analysis for this company, I would say we target the R&D industry. Create a cushy margin, say $15,000, and then we only need to focus on selling 50 units a year. I can then spend time going to trade shows and other outreach to market the extruder. Further, I can provide really good customer service to match the price tag. Obviously, if you set the price too high, then potential customers will just build it themselves.

@@DrDFlo Thank you so much for explaining this to me. I knew I was missing something but couldn't really find a good amount of info on it. Your channel is awesome and you consistently put out incredible content. You're really good at explaining complex things at a level accessible to the rest of us and the way you share it is very engaging! Keep being you!

I just watch homies videos and pretend like I understand what he is talking about.

You say that pellet extruders can have issues with small moves due to the need to build pressure. Could this be fixed by decoupling the requested flow rate and the screw motor? If you had a way of sensing the pressure in the nozzle then maybe you could have the nozzle pressure controlled separately from the flow rate requested by the Gcode file. Or maybe some changes to how the slicer works to allow it to compensate for the screw extruded and continue spinning the screw between moves.

Why not print one of those dairy queen stainless steel lid sleeves for your containers so more of the reclaim falls in?

Have you got a jam in screw and how easy was to remove the screw then?

Screw is incredibly easy to remove. You have access to the back tang of the screw, so it can be tapped out with a brass screw driver.

Row row benchie boat, gently down the stream :-). Sending the giant benchie down the Niagara Falls might be a clickbait worthy content for you to attract more subscribers and get people into makerworld. Of course picking up the benchie with GPS tracker at later stage down the stream to see how tough it is.

i wonder if a pellet extruder could benefit from some sort of valve to block the flow of plastic and maintain pressure during travel moves instead of a standard "retraction"